Process & contact

CCm

CCm Technologies Carbon Capture and Utilisation

Updated 2/2022

Input materials

Digestates of sewage sludge, food waste, manure or other biowastes.

In some cases, also other secondary materials e.g. wood chips, organic fibres, biomass ash,

Offgas CO2

Output products

Pelletised organo-mineral fertiliser, containing stabilised N and P.

Field tests of the fertiliser product show compatibility of the pellets with existing farm fertiliser equipment: rotating discs up to 36m wide spreading radius), crop performance comparable to commercial mineral fertilisers and positive impacts on soil bioflora, water retention, soil carbon and reduced nutrient runoff.

Process description

Ammonia captured from digestate is used to capture (as carbonate) CO2 from digester biogas (mixed off-gas or separated CO2 stream from biomethane). This is then combined with organics in digestate cakes, further stabilising the nitrogen and carbon. The product is then dried and pelletised, to produce a stable organo-mineral fertiliser (OMF).

Additionally, CCm are operating a pilot unit Pilot (4 m3/day) at Yorkshire Water Caldervale site, UK, to remove and recover phosphorus as struvite from P-rich sludge dewatering streams, using magnesium and ammonia. The output integrates the phosphorus into the stable organo-mineral fertiliser pellets. Aim: 75% P reduction from liquors. Startup planned Q2 2022.

Operating status

Industrial demonstrator at Kew Technology Sustainable Energy Centre, UK, to produce OMF fertiliser. Output: 500 t/yr. Inputs: biochar, digestate, recovered CO2 from enhanced thermal conversion technology. Operational in Q1, 2022

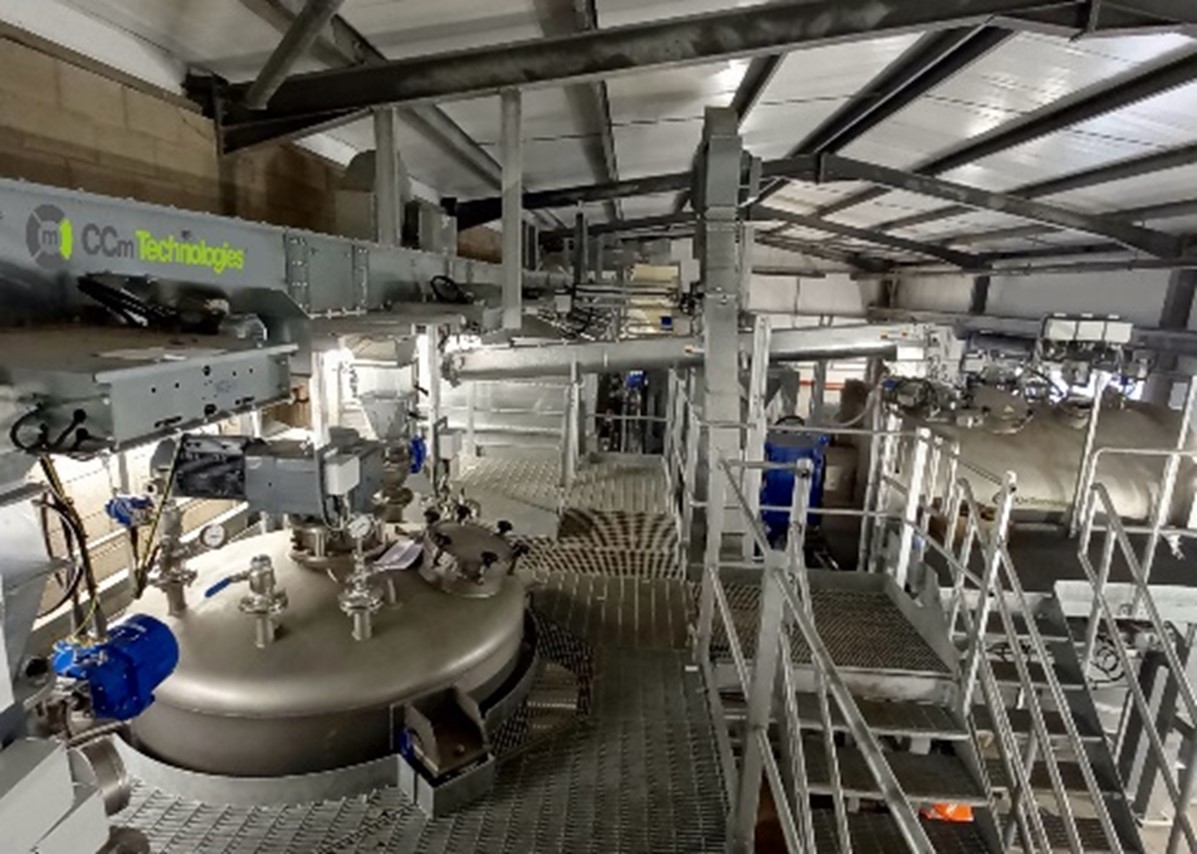

Industrial demonstrator at Severn Trent Water Minworth site, UK (photo). Output 10 000 t/yr OMF fertiliser pellets. Input capability: sewage sludge, biomass ash, recovered CO2, recovered ammonia. Operational from 2021.

Full scale plant at Walkers potato processing plant (Pepsico, Leicester, UK). Outputs: 12 000 t/yr OMF fertiliser pellets. Inputs: food waste digestate, recovered CO2. Operation start Q2, 2022.