Process & contact

www.stiesdal.com/skyclean

Input materials

Digestate, straw & any other crop residues, pelletized and with 5 – 10% moisture content.

Output products

Depending on the input, e.g. straw gives a biochar with high water holding capacity, 75.7% total carbon, and an ash content of 18.1%. There is - among other nutrients - 2.9% K, 0.9% N and 0.2% P. Biogas digestate gives a biochar with 63% carbon, 31.6% ash, 2.1% P, 1.6% N and 1.5% K, and also high water retention.

Process description

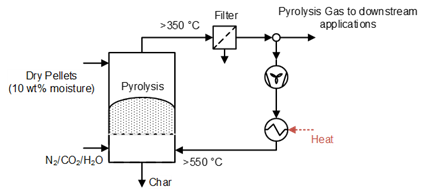

The Stiesdal SkyClean pyrolysis process is based on an updraft pyrolysis reactor design (see figure).

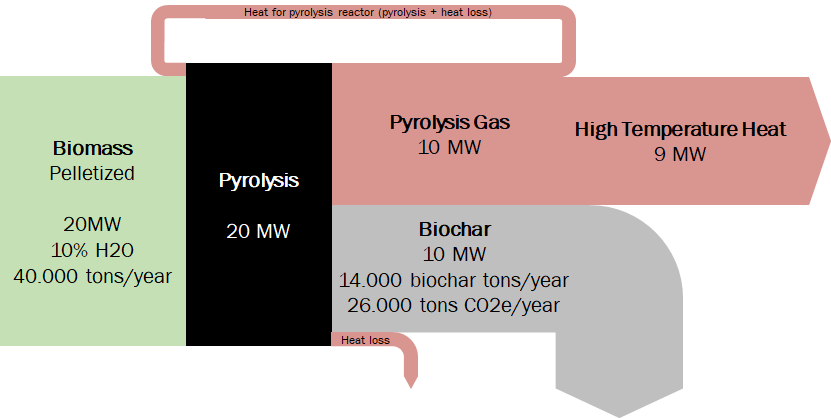

The full scale Stiesdal SkyClean 20MW pyrolysis plant requires ca. 40.000 MT biomass (as dry matter) input and will produce ca. 10 MW pyrolysis gas, and about 10 MW in 14.000 MT biochar. The pyrolysis gas can be used directly for heat production. Alternatively it can be condensed to bio-oil, or further refined to syngas and methane. Approximately 2 MW heat will be required for drying and pelletizing of biomass in a setup where the biomass is supplied to the plant with 30% dry matter e.g. from a biogas plant.

The various energy flows are represented in the Sankey diagram.

Operating status

There are two demo/pilot installations in Denmark with 200 kW (50 kg feedstock per hour) and 2MW (500 kg feedstock per hour) capacity running continuous pyrolysis operation since about two years. The first commercial scale Stiesdal SkyClean 20MW pyrolysis plant is currently under construction in Denmark built in connection with a biogas plant with expected commissioning in October 2023.