Newsletter about nutrient stewardship - European Sustainable Phosphorus Platform (ESPP)

Please subscribe www.phosphorusplatform.eu/Subscribe

Link to www.phosphorusplatform.eu/eNews074

Download as PDF

White Ammonia – Nitrogen Recovery

1st White Ammonia Research Meeting (WARM) - 7th June 2023

Call for nominations of nitrogen recovery science papers

ESPP moving forward on Nitrogen Recovery

Consultations, calls, surveys

EU public consultation on Critical Raw Materials

EFSA call for scientific experts

Open and upcoming Horizon Europe research funding calls related to nutrients

IFS survey on definition of “plant nutrient”

Looking for “best of” science publications on Nitrogen Recovery

Call for experts for EU Fertiliser Market Observatory

EU (Strategic and …) Critical Raw Materials Act (CRM)

Phosphate Rock and P4 stay on EU Critical Raw Materials List

JRC Foresight Report on materials for strategic technologies

SCRREEN2 Fact Sheet

Policy

United Nations adopts 50% nutrient loss reduction target

Sewage plants are currently incompatible with small river & stream water quality

Summary of 15th CRU Phosphates conference

ESPP new member

European Biochar Industry Consortium (EBI)

Research

IFS webinar debate on definition of “plant nutrient”

Vegan diets require lower N, P and K fertiliser inputs

Phosphorus Use Efficiency (PUE) is improving in China but is still low

Phosphorus uptake controls plant response to increased atmospheric CO2

Nutrient recycling

Lex4Bio survey on “Bio-Based Fertilisers”

EasyMining LIFE RE-Fertilize N-recovery webinar

Implementation of German sewage P-recovery obligation

Phosphorus in sewage sludge incineration ash (SSIA) is not short-term plant available

Phosphorus uptake from nine secondary materials and P extraction methods

Freeze concentration to concentrate digestate RO liquor

Stay informed

ESPP members

White Ammonia – Nitrogen Recovery

1st White Ammonia Research Meeting (WARM) - 7th June 2023

ESPP is organising a first White Ammonia and N-recovery Research Meeting (WARM) in Brussels and hybrid, Wed. 7th June 2023 (plus nitrogen recovery site visit 6th June). This will showcase research and innovation into nitrogen recovery and make links from EU R&D policy to industry implementation.

This is within EU Green Week, Brussels, and back-to-back to the 6th NH3 Event (& 6th Power to Ammonia conference), Europe’s biggest ammonia event, Rotterdam 8-9 June 2023 (one hour train from Brussels).

Details coming soon on http://www.phosphorusplatform.eu/events

Call for nominations of nitrogen recovery science papers

ESPP is preparing a SCOPE Newsletter special presenting the “best of” of recent scientific papers or reports on Nitrogen Recovery and Recycling. This will summarise a selection of around 25 scientific publications for the last few years, similar to SCOPE special editions on climate change – eutrophication links (n°137) or phosphorus sustainability (n°128).

Selection will target papers representing significant knowledge progress in N-recovery, both technical recovery (N recycling to industry or fertilisers) and biological or other N recycling routes, in particular: operating experience at full/pilot scale or innovative technologies leading to N-recovery in a form likely to be a marketable product.

Please send copies of or links to papers you suggest should be included, your own or other authors’, to .

ESPP moving forward on Nitrogen Recovery

ESPP is establishing a Start-Up Steering Committee to take forward actions on nitrogen recovery and recycling. First meeting online 29th March. Persons interested to engage are invited to contact This working committee will function by online and/or physical meetings and email.

ESPP has also completed the detailed summary of the 19th January Nitrogen Recovery Workshop, published as SCOPE Newsletter n°145 with summaries of presentation and discussions, and key facts on the different nitrogen recovery technology providers.

Consultations, calls, surveys

EU public consultation on Critical Raw Materials

Consultation open to 16th May 2023 for public input on draft EU Critical Raw Materials Act, covering Critical and Strategic Raw Materials Lists, including phosphate rock and P4 – details see article below. Consultation here.

EFSA call for scientific experts

EFSA (European Food Safety Authority) call for candidates for its scientific panels and committee, including BIOHAZ (Biological Hazards), the committee dealing with safety of animal by-products use in fertilisers and animal feeds. The call is open for scientists to 3 April 2023.

EFSA “Call for Expressions of Interest for Membership of the Scientific Panels and the Scientific Committee of EFSA 2023” HERE

Open and upcoming Horizon Europe research funding calls related to nutrients

Several open and upcoming Horizon Europe calls concern nutrients, in particular soon-to-open calls on N and P regional boundaries and recycled nutrient fertilising products (first deadline February 2024). In December 2022, the European Commission adopted the 2023-24 work programme of Horizon Europe – the EU’s funding for research and innovation.

At the moment, ten calls open are related to nutrients. One call, closing soon on 23rd March 2023, aims at developing EU advisory networks on the optimal fertiliser use, while other calls with a submission deadline on the 28th March 2023 are focused on benefits of leguminous crops and their contribute to reducing the EU’s dependency on imports of nitrogen fertilisers and protein crops for feed, sustainable and circular management and use of water resources, including nutrient recovery, and innovative solutions in agriculture for water availability and quality. Two stages calls belonging to the “Clean environment and zero pollution” topic, first stage closing on 28th March 2023, are open on manure use to mitigate GHG emissions and minimize nutrients/contaminants dispersion in the environment and bio-based platform chemicals, additives, materials or products. On the 12th April 2023, five calls indirectly related to nutrients will close, dealing with strategies to improve yields in organic cropping systems, activities for the European Partnership Water Security for the Planet (Water4All), sustainable production of renewable energy at farm-level and urban farming impacts.

Particularly relevant calls for nutrient research will open on 17th October 2023, with a (first) submission deadline 22nd February 2024 (both one- and two-stage calls):

- respecting safe ecological and regional nitrogen and phosphorus boundaries,

- recovered / recycled fertilising products from secondary raw materials,

- irrigation practices and technologies in agriculture, including potential of sewage sludge and other biowaste streams, ensuring high agronomic efficiency of the nutrients they contain,

- inputs in organic farming,

- nutritional value of animal feed under different production management conditions,

- decentralised approaches for water and wastewater management,

- monitoring of water quality in urban areas,

- technologies for preventing and controlling pollution from bio-based industries.

ESPP is interested to support networking, dissemination and communication activities. Please contact Veronica Santoro for more information and possibilities (). See our ESPP list of running and finished EU and national funded nutrients research projects.

ESPP research activities and ESPP nutrient related R&D project list www.phosphorusplatform.eu/R&D

IFS survey on definition of “plant nutrient”

See article below. Survey open HERE.

Looking for “best of” science publications on Nitrogen Recovery

See above and HERE

Call for experts for EU Fertiliser Market Observatory

European Commission (DG Agriculture) call for experts to participate in EU Fertilisers Market Observatory as a group of experts on availability and affordability of fertilisers, following the Commission Communication on fertilisers supply and price (November 2022, see ESPP eNews n°72). Candidates should be representatives of organisations representing stakeholders of at least 10 EU Member States active in the fertilisers supply chain. The Observatory will have up to 20 members and will play a consultative role, providing the Commission with advice and expertise on factors impacting the fertilisers market and market developments.

“Commission calls for applications to join the upcoming EU Fertilisers Market Observatory”, 16th march 2023. Deadline: 4th April 2023 HERE

EU (Strategic and …) Critical Raw Materials Act (CRM)

Phosphate Rock and P4 stay on EU Critical Raw Materials List

But the proposed CRM Act defines two levels of importance: “Strategic” and “Critical”. Strategic are related to electronics. New targets and tools are proposed for these, but not for “Critical”, so not for Phosphate Rock or P4.

The Act is a proposed EU Regulation, published 16th March 2023, which is now open to public consultation until 16th May 2023 then will go to the European Parliament and Council for discussion and possible amendment and modification before adoption.

The “Strategic Raw Materials” are defined as those needed for (Preamble §4) “strategic technologies underpinning the green and digital transitions or for defence or space applications” and are listed in Annex I (16 materials, all metals or related elements). These are a subset of 34 Critical Raw Materials (CRMs) listed in Annex II and defined as (Preamble §5) “all strategic raw materials as well as any other raw materials of high importance for the overall Union economy and for which there is a high risk of supply disruption” and are listed in Annex II. Both lists will be reviewed every four years.

“Phosphate Rock” and “Phosphorus” (meaning P4/derivatives) are maintained in this proposed 5th CRM list, which now includes 34 materials, increased from 30 in the 4th CRM list (2020, see ESPP eNews n°48). Arsenic, helium, copper, nickel (battery grade) and feldspar* are added; natural rubber is deleted. However, they are not included in the subset of 16 Strategic Raw Materials (SRMs).

|

The proposed EU Critical Raw Materials Regulation and its annexes include “Phosphorus” and “Phosphate Rock” as CRMs, but provide no definition of these terms. Similarly for the previously published updates of the CRM List. A recent definition can be found in the SCCRREEN Factsheet (see below) as follows: |

|

|

CRM “Phosphate Rock” |

CRM “Phosphorus” |

|

“In effect covering phosphorus P in different forms in fertilisers, animal feed, chemicals and other uses.” |

“Referring to elemental phosphorus P4, often known as white phosphorus.” |

|

ESPP comment: around 95% of global phosphate rock use is for agriculture, of which around 90% for fertilisers. |

ESPP comment. P4 is produced from phosphate rock in specific furnaces. P4 production is <2% of phosphate rock use. The EU today has no P4 furnace and depends entirely on imports. See SCOPE Newsletter n°136 |

The Commission’s proposals for the SRM (Strategic) list are indicated to be based on the new JRC Foresight Report (2023), see below. It is therefore very surprising that the essential role of P4 derivatives for electronics, batteries, renewable energy is not recognised and that “Phosphorus” is not included in the list of Strategic Raw Materials.

White Phosphorus (P4, referred as “Phosphorus” in the EU CRM documents) is necessary for battery electrolytes, microchip etching, semiconductors, fire safety, all of which are essential for the “Strategic” sectors of green energy, digital and aerospace. Indeed, “Phosphorus” is identified in the accompanying JRC Foresight Report, as used in batteries, photovoltaics, hydrogen iron/arc furnaces, laptops/smartphones and space/satellites and as having high supply risk (see below).

As per ESPP’s input to the public consultation in November 2022 (HERE), ESPP notes that food materials are excluded from the definition of CRMs but we regret that the proposed CRM Act does not recognise the important links between CRMs and food security. This could be achieved by indicating in the proposed CRM Act the links to the Commission Communication on Fertilisers price and supply (see ESPP eNews n°72).

The proposed CRM Regulation sets out actions to be engaged, at either EU or Member State levels. As written, it seems that some of these actions apply to all Critical Raw Materials, and some only to Strategic Raw Materials (this could be modified by Parliament/Council).

|

Art: |

Actions proposed for STRATEGIC SRMs only |

|

1 |

EU targets for production of raw materials (extraction: 10% of EU consumption), processing (40%), recycling (15%), supply diversification (no country > 65% of supply) |

|

5 - 17 |

“Strategic Projects”: expected to make a meaningful contribution to EU supply of SRMs |

|

24 |

Possibility of EU-level joint supply purchasing systems. |

|

Art: |

Actions proposed for ALL CRMs |

|

18 |

Each MS to define national exploration programmes |

|

19 |

EU-level monitoring of supply risk, covering: trade flows; demand and supply; concentration of supply; Union and global production and production capacities at different stages of the value chain … Stress test at least every three years, considering supply chain, processing and recycling, alternative sources |

|

25 |

Each Member State to adopt a national programme to increase collection of waste with high CRM recovery potential and ensure appropriate recycling, increase re-use, increase use of secondary raw materials including by taking recycled content into account in public procurement. National systems may include financial incentives. The Commission will adopt a list of waste streams considered as having high CRM recovery potential. |

|

26 |

Inventory and feasibility assessment of potential recovery of CRMs from “extractive wastes”. As currently written, ESPP suggests that this will not apply to phosphogypsum stacks, as these are processing waste, not from “extractive” industries (as defined in 2006/21/EC). |

|

30 |

The Commission is empowered to adopt Environmental Footprint calculation rules and sustainability certification schemes for CRMs. |

|

33 |

Strategic partnerships between the EU and third party countries for CRM supply. |

Definitions

The proposed Regulation includes a considerable number of definitions. Although these are “for the purposes of this Regulation”, they may pose jurisprudence. As well as some unexpected definitions (e.g. tumble dryer, dishwasher …), the definitions include:

- Reserves: all mineral occurrences that are economically viable to extract.

- Raw material: a substance in processed or unprocessed state used as an input for the manufacturing of intermediate or final products, excluding substances predominantly used as food, feed or combustion fuel.

- Recycling: any recovery operation by which waste materials are reprocessed into products, materials or substances whether for the original or other purposes.

- Recovery: any operation the principal result of which is waste serving a useful purpose by replacing other materials which would otherwise have been used to fulfil a particular function, or waste being prepared to fulfil that function, in the plant or in the wider economy.

JRC Foresight Report on materials for strategic technologies

Forecasts for EU material demand and supply risks for strategic technologies. “Phosphorus” (P4) is cited for all five sectors and as supply-critical. This seems to include misunderstandings, but other essential uses of P4 are missing. The report covers 15 technologies in five strategic sectors: renewable energy, e-mobility, industry, information & communications technology (ITC) and aerospace/defence. P4 is identified as used in lithium ion batteries, solar photovoltaics (PV), hydrogen direct reduced iron and electric arc furnaces (H2-DRI), smartphones – laptops and space launchers – satellites. Phosphate rock is identified as used in data transmission networks.

The report identifies ‘Phosphorus’ (P4) as the raw material with the highest supply risk for batteries and for H2-DRI (p. 20, p77) and amongst the 15 with highest supply risk for data storage & servers, PV, smartphones-laptops and space-satellite, with 79% of production in China (p.76. Note: JRC indicated 87% in the P4 MSA 2021, see ESPP eNews n°58). However, the need for P4 in batteries seems to be based on the error that P4 is needed to produce lithium iron phosphate for LFP batteries (to ESPP’s understanding, this is incorrect: battery grade LiFePO4 can be and already is today produced via purified merchant-grade phosphoric acid, see SCOPE Newsletter n°136). The JRC Foresight Report further suggests that LFP batteries will compete with fertiliser production for phosphate rock (this is referenced to only one P-rock mine project company’s promotion, Epstein 2022). Not only is this largely wrong (see summary of CRU Phosphates 2023 below), it also suggests the report is confusing “Phosphate Rock” with “P4”. P4 is however a necessary input to produce lithium hexafluorophosphate (LiPF6), which is cited in the Foresight Report for batteries (electrolytes) and tablets-laptops.

The Report also notes (p.90) that P4 is increasingly essential for fire safety, under data storage and servers, stating “increasing move to green materials and chemicals … Phosphorus flame retardants (PFRs) are often proposed as alternatives to brominated flame retardants (BFRs)”. Flame retardants are also needed in smartphone-laptops, but – without explication nor coherence – the Report apparently does not consider the need for phosphorus in fire safety for wind turbines, photovoltaics, heat pumps, space-satellites, 3D-printing …

Gallium indium phosphide and indium phosphide, which do need P4 for their production, and which are used in semiconductors, are cited as needed for photovoltaics and data storage. Other essential uses of P4 in the considered technologies are not cited, in particular thermal phosphoric acid for micro-chip etching, and phosphine for semi-conductor doping (partial modification of Si to P in semiconductors).

Phosphate rock is indicated as needed for data transmission networks, but for no other technology (p84), with no explanation (p.81), but P4 is not cited whereas it is used in fire safety of cables, semiconductors, microchips. Again this suggests that the Report is confusing these two CRMs.

Overall, the designations of which technologies require “Phosphorus” (meaning P4/derivatives) and “Phosphate Rock”, and why, are largely unexplained, often incoherent, and in some cases seem to be based on erroneous information and confusion between these two CRMs. Despite this, and even more so when considering the essential uses of P4 which are not cited or only partly taken into account (chip etching, fire safety, semiconductor doping), the Foresight Report identifies P4 as needed for all the strategic sectors and a significant number of the technologies, and as one of the materials with the highest supply chain risk (this is certain: no production of P4 in the EU, and import dependency on three countries: China, Vietnam and Kazakhstan).

ESPP therefore considers it very surprising that the CRM “Phosphorus” (P4 and derivatives) is not included in the proposed list of EU Strategic Raw Materials, see above.

SCRREEN2 Fact Sheet

Published SCRREEN2 input to CRM Act confuses the two CRMs ‘Phosphorus’ (P4) and ‘Phosphate Rock’ and contains various errors. ESPP had understood that the EU-funded SCRREEN2 project (3 million € EU money, led by the French Atomic Energy Commission CEA), was supposed to deliver input information to support the update of the CRM List, in the form of SCRREEN2 CRM “Factsheets”. The project has apparently failed to do this in time for Phosphate Rock and P4 in that the draft Factsheet (not dated, online 19th March 2023) contains various errors suggesting a lack of relevant understanding (e.g. sodium is cited as one of the three main plant nutrients p.16) and confuses the CRM “Phosphate Rock” with “Phosphorus” (P4) by treating both in the same Factsheet. The separation into two Factsheets of the two CRMs Phosphate Rock and P4 was requested, but is apparently not done in time to input to the CRM Act. Also, the authors do not seem to understand the chemical difference between “phosphate” and “phosphorus”: on p.26 phosphate is calculated to have the molar weight of the element phosphorus. ESPP pointed to such problems already at SCRREEN workshops and in letters in July and September 2022 (see HERE). Many comments are not taken into account in this draft Factsheet. This failure of SCRREEN may explain the apparently confused treatment of P4 in the JRC Foresight Report.

* Feldspar: a naturally occurring alumino-silicate mineral, source of alumina for e.g. glassmaking, ceramics.

European Commission Critical Raw Materials web page:

https://single-market-economy.ec.europa.eu/sectors/raw-materials/areas-specific-interest/critical-raw-materials_en

European Commission press release, 16th March 2023 IP_23_1661 “Critical Raw Materials: ensuring secure and sustainable supply chains for EU's green and digital future” – includes links to Commission Communication, FAQ, etc. https://ec.europa.eu/commission/presscorner/detail/en/ip_23_1661

Proposed EU Critical Raw Materials Act, COM(2023)160, 16th March 2023 https://single-market-economy.ec.europa.eu/publications/european-critical-raw-materials-act_en

JRC Foresight Report 2023 “Supply chain analysis and material demand forecast in strategic technologies and sectors in the EU – A foresight study”, S. Carrera et al., ISBN 978-92-68-00339-8 (266 pages) https://publications.jrc.ec.europa.eu/repository/handle/JRC132889

SCRREEN2 (“Solutions for CRitical Raw materials - a European Expert Network 2) draft FactSheets https://scrreen.eu/crms-2023/

Public consultation open to 16th May 2023 https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/13597-European-Critical-Raw-Materials-Act_en

Policy

United Nations adopts 50% nutrient loss reduction target

The COP15 Kunming-Montreal convention Global Biodiversity Framework, December 2022, includes the target to reduce nutrient losses by 50% by 2030, that is the same nutrient loss reduction target as the EU Green Deal (Farm-to-Fork and Biodiversity Strategies, both May 2020, see SCOPE Newsletter n°139). Target n°7 of Global targets for 2030 aims to reduce all pollution to levels not harmful to biodiversity and ecosystems and specifies “reducing excess nutrients lost to the environment by at least half, including through more efficient nutrient cycling and use” as well as reducing by 50% risks from pesticides and hazardous chemicals and addressing plastic pollution.

United Nations Convention on Biological Diversity, decision adopted 7-19 December 2022 Kunming-Montreal Global Biodiversity Framework https://www.cbd.int/doc/decisions/cop-15/cop-15-dec-04-en.pdf

Sewage plants are currently incompatible with small river & stream water quality

Statistical analysis suggests that sewage works discharge flow > 6.5% of low flow* of small rivers and streams means likely failure to achieve Good Quality Status required by the EU Water Framework Directive. The correlation is not found in larger rivers (Strahler order >3). Nearly 60% of the 1.7 million km of Europe’s rivers and streams are not in Good Ecological Status, usually as a consequence of multiple pressures. The correlation between higher proportion of (low) flow from sewage works discharge to quality status failure held for smaller rivers and streams held not only for the EU overall, but also for 7 out of 10 of the largest catchments (not for the Rhône catchment) and to some extent for all of 6 river types. Across Europe, 82% of length of smaller rivers and streams were not in Good Ecological Status. A maximum recommended discharge / river Q10* low flow ratio of 6.5% was derived, based on 50% probability of achieving Good Quality Status. If 90% probability of Good Quality Status was targeted, this would result in a ratio of 12%. Nearly 60% of segments of small rivers and streams in Europe today exceed the 6.5% ratio and this concerns 9 700 of the EU’s 26 500 sewage works (mainly smaller sewage works: 2/3 < 10 000 p.e.). These sewage works are distributed across the UK, but >80% of sewage works exceed the 6.5% ratio in Bulgaria, Cyprus, Greece, Hungary, Netherlands, Portugal and Spain. Solutions to mitigate discharges to smaller rivers and streams include re-routing discharge to larger rivers, additional wastewater processing, appropriate re-use of wastewater or restoration of ecosystems.

* 10% quartile low flow

“Are waste-water treatment plants failing to protect the ecological health of European streams?”, EU Commission Science for Environment Policy n°595, 15th February 2023 https://environment.ec.europa.eu/news/are-waste-water-treatment-plants-failing-protect-ecological-health-european-streams-2023-02-15_en

“Why wastewater treatment fails to protect stream ecosystems in Europe”, O. Büttner et al., Water Research 217 (2022) 118382 https://doi.org/10.1016/j.watres.2022.118382

Summary of 15th CRU Phosphates conference

Phosphates 2023 took place in Istanbul, 27th February – 1st March 2023, with 370 participants, 50 industry stands and nearly 30 technical presentations. Ludwig Hermann, for ESPP, presented European policy perspectives.

Humphrey Knight, CRU, summarised market challenges of 2022: prices hit a 15-year high, resulting in a significant drop in demand. Despite high crop sales prices, phosphate fertiliser affordability was unfavourable. Demand for high-grade rock fell more than for low-grade rock. With the fall in demand for phosphate fertilisers, industry thus managed to ride through major supply disruptions. China’ exports fell by nearly 50% in 2022, and may remain reduced as the country’s priority turns to national supply. Contrary to initial expectations, Russia was able to continue exporting fertilisers, but showed a considerable decrease in exports of high-grade phosphate rock comparable to other high-grade rock suppliers. Price and supply challenges are expected to become less acute in 2023.

Technical presentations particularly addressed speciality fertilisers and sustainability. Ravi Hiremath, Solvay, presented a chemical additive (ACCO-PHOS) to chelate cadmium, copper, arsenic and other metals out of phosphoric acid, so enabling producing of fertilisers with low heavy metal levels. Michael Meyer, EasyMining, presented the Ash2Phos process to recover phosphorus as high-quality calcium phosphate from sewage sludge incineration ash. Agnes von Garnier, Collin Bartlett and Hannes Storch, Metso Outotec, presented a process to recover sulphuric acid from phosphogypsum stockpiles, to address the expected shortfall in sulphuric acid supply when supply from oil refineries slows down. Hadrien Leruth, Prayon Technologies, presented the GetMoreP and Ecophos processes, as routes to upgrade secondary phosphorus sources, low grade phosphate rock or phosphate mine tailings to dicalcium phosphate.

Sam Adham, CRU, discussed expected future development of Lithium Iron Phosphate (LFP) batteries, as a lower cost alternative to Lithium Ion. Phosphate rock consumption for LFP battery cathode production is disproportionally high due to very high purity requirements. This could be balanced by co-production of merchant grade phosphoric acid carrying the impurities that have been removed from LFP grade. Demand for phosphate rock for LFP production is expected to reach 4 – 5 Mt/y (rock) per year in coming decades, compared to current total world production of around 200 Mt/y of phosphate rock (see ESPP FactSheet).

Several phosphate rock mining projects were presented, in Europe (Norge Mining, Stavanger Region, Norway), South Africa (Schiel Phosphate Mining Project, Limpopo Province), Canada (First Phosphate, Quebec) and Australia (Verdant Minerals and Arianne, both in the Northern Territories). Most of them target high grade resources suitable for LFP batteries and other industrial uses.

15th CRU Phosphates Conference (2023)

The 16th CRU Phosphates Conference will take place in Warsaw, Poland, 26-28 February 2024

https://events.crugroup.com/phosphates/home

ESPP new member

European Biochar Industry Consortium (EBI)

EBI is the voice of leading players in the rapidly developing European biochar industry. EBI supports biochar as a high-potential solution for phosphorus recycling (from sewage sludge and certain animal by-products), carbon mitigation, and agricultural soil improvement. For a broad range of feedstocks, particularly those where contaminants or sanitary safety pose challenges, such as sewage sludge or certain animal by-products, pyrolysis enables a circular economy. By increasing awareness of the benefits of biochar and advocating for science-backed regulations and industry standards, EBI is working towards developing the European biochar industry into an important and established sector. The overall aim is to contribute to Europe’s fight against climate change. The sector development is already in process, by end of 2022, the EU had 130 installations, producing around 53 000 t/y of biochar. See EBI Market Report here. EBI has 83 members, who are pyrolysis plant owners and operators, users, system and technology providers. Depending on the process and input materials, which can include plant-based, non-plant-based and waste streams, biochars can be used in animal feed, air, soil and water purification (activated carbon), as well as fertilisers or soil improvers. Moreover, the market potential of biogenic carbon-based construction materials and polymers obtained through pyrolysis is growing fast. By becoming a member of the ESPP, EBI finds an important ally in advancing nutrient recovery and waste stream valorisation, including pyrolysis as a treatment path for residues like sewage sludge and work towards a circular economy as well as the creation of quality carbon removals. EBI has recently launched advocacy to request that the European Commission revisit the current exclusion of sewage sludge biochar from the Fertilising Products Regulation (CMC14). The position paper is based on a reassessment of recent data showing that pharmaceuticals, microplastics and PFAS are eliminated in pyrolysis under appropriate conditions (see ESPP eNews n°73).

EBI is the voice of leading players in the rapidly developing European biochar industry. EBI supports biochar as a high-potential solution for phosphorus recycling (from sewage sludge and certain animal by-products), carbon mitigation, and agricultural soil improvement. For a broad range of feedstocks, particularly those where contaminants or sanitary safety pose challenges, such as sewage sludge or certain animal by-products, pyrolysis enables a circular economy. By increasing awareness of the benefits of biochar and advocating for science-backed regulations and industry standards, EBI is working towards developing the European biochar industry into an important and established sector. The overall aim is to contribute to Europe’s fight against climate change. The sector development is already in process, by end of 2022, the EU had 130 installations, producing around 53 000 t/y of biochar. See EBI Market Report here. EBI has 83 members, who are pyrolysis plant owners and operators, users, system and technology providers. Depending on the process and input materials, which can include plant-based, non-plant-based and waste streams, biochars can be used in animal feed, air, soil and water purification (activated carbon), as well as fertilisers or soil improvers. Moreover, the market potential of biogenic carbon-based construction materials and polymers obtained through pyrolysis is growing fast. By becoming a member of the ESPP, EBI finds an important ally in advancing nutrient recovery and waste stream valorisation, including pyrolysis as a treatment path for residues like sewage sludge and work towards a circular economy as well as the creation of quality carbon removals. EBI has recently launched advocacy to request that the European Commission revisit the current exclusion of sewage sludge biochar from the Fertilising Products Regulation (CMC14). The position paper is based on a reassessment of recent data showing that pharmaceuticals, microplastics and PFAS are eliminated in pyrolysis under appropriate conditions (see ESPP eNews n°73).

European Biochar Industry Consortium (EBI) www.biochar-industry.com

EBI European Biochar Market report 2022/2023 HERE

Research

IFS webinar debate on definition of “plant nutrient”

International Fertiliser Society webinar proposed a new definition of a “plant nutrient”, aiming for a wider concept of “one nutrition”, following 2022 concept paper from scientists and industry (IFA). A survey is now open for input. The authors suggest that current definitions of “plant nutrient” are widely interpreted to mean that the nutrient must be essential for all plants, whereas science is today showing that a number of elements can improve plant growth and development, where this was not previously recognised (e.g. silicon, iodine), or may be only essential for some crops in some conditions (e.g. aluminium for certain tea varieties, sodium for some species). The authors note that US regulation currently defines a plant nutrient as being “essential for normal growth of plants” but does not specify for all plants*.

The authors propose as a new definition “A mineral plant nutrient is an element which is essential or beneficial for plant growth and development or for the quality attributes of the plant or harvested product, of a given plant species, grown in its natural or cultivated environment”.

They call for a consensus agreement on a new definition of “Plant Nutrient”, suggesting that this process should bring together scientists, industry and regulators. ESPP suggests that this is the logical remit of standardisation (ISO). The authors also suggest that a global body should be established to periodically review evidence as to which elements can be considered to meet the new definition under which conditions.

ESPP notes that the International Standardisation Organisation (ISO) has fixed a clear and simple definition of Plant Nutrient: “substance that is essential or beneficial for plant growth” (ISO 8157:2022 Fertilizers, soil conditioners and beneficial substances — Vocabulary).

ESPP also notes that the EU Fertilising Product Regulation (FPR) uses the term “nutrient” but does not include a definition for it. However, the FPR does in effect specify a limited list of recognised nutrients, in that it defines a Macronutrient fertiliser (cf. PFC1(C)(I)(a)(ii)) as providing N, P, K, Ca, Mg, Na or S and a Micronutrient fertiliser (PFC1(C)(II)) as providing B, Co, Cu, Fe, Mn, Mo, Zn.

* Source: AAPFCO “Official Publication” n°76, 2003, which indicates as the definition for “Secondary Nutrient (T-9, page 94) “those other than the primary nutrients that are essential for the normal growth of plants and that may need to be added to the growth medium …”

IFS (International Fertiliser Society) webinars: https://fertiliser-society.org/product-category/recordings-and-webinars/webinars/

“What is a plant nutrient? Changing definitions to advance science and innovation in plant nutrition”, P. Brown, F-J. Zhao, A. Dobermann, Plant Soil (2022) 476:11–23 https://doi.org/10.1007/s11104-021-05171-w

IFS webinar “A new definition of ‘Plant Nutrient’ and its implications for fertilizer regulations globally”, 22nd February 2023 https://fertiliser-society.org/ifs-events/2023-ifs-technical-webinar-programme/

Survey open: https://docs.google.com/forms/d/e/1FAIpQLSfxAqeOSMCwfszUov9PXv78zdFqd7Dz8ONf_jdvcfH9tDw3wA/viewform

Vegan diets require lower N, P and K fertiliser inputs

Fertiliser requirements are calculated for vegan vs. omnivore diet, with different animal feed use efficiency, crop use efficiency and recycling rates. Overall results are presented as total mass of fertiliser, but calculations are presented separately for N, P and K. Key influencing parameters are identified as: livestock feed use efficiency (IFE), fraction of animal manures reaching and taken up by crops (depending on manure and agri-food waste recycling / reuse scenarios, and crop use efficiency) and N-loss during composting of manures and food wastes. It is underlined that in intensive livestock systems not all manure is returned to land (e.g. China only 35-75% of livestock manures returned to land, Ma 2010, Hou 2013) or manure may be applied in excess to some land or not distributed usefully on land*. The authors conclude that estimates of fertiliser requirements vary widely depending on the coefficients used for these different efficiency factors. With a relatively high hypothesis of 70% of return and uptake of manure by crops, an omnivore diet would require (table 5) 12 – 120 x more P-fertiliser than a vegan diet and 5 – 30 x more N-fertiliser. These estimates compare to estimates published by other authors of 20 – 36 x for P and 6 – 13 x for N. The authors note that Van Kernebeek 2016 estimated that including some meat in diet would be optimal, but that this assumes that livestock and animal feed crops are produced on marginal land and that there is no competition for this land space for other uses (e.g. energy crops).

* ESPP notes that it is nearly inevitable that manure will not be appropriately distributed even in extensive livestock systems, because animals tend to concentrate excretion at feeding, drinking or rumination points – see Kreuzer in SCOPE Newsletter n°131.

See also Lancet Commission, Springmann et al. in ESPP eNews n°48

“Savings in fertilizer requirements from plant-based diets”, L. Harvey, Resources, Conservation & Recycling 190 (2023) 106820 https://doi.org/10.1016/j.resconrec.2022.106820

Phosphorus Use Efficiency (PUE) is improving in China but is still low

Despite improvements, China still has low PUE (c. 40% national average) and significant phosphorus surplus (over 25 kgP/ha), with high regional variations. Both PUE and surplus are however improving since around 2005 – 2015. Phosphorus flow analysis is based on data for crop yields, straw, livestock, fertiliser and cultivated areas for Chinese official data, FAO and literature. Assessment was made at the national level for 1990 – 2018 and at the provincial level (grouped into seven regions) for 2005 – 2018. Around 7.5 MtP/y were input to China’s farmland over this period, of which c. 80% in mineral fertiliser, whereas the average output was <3 MtP/y. Higher phosphorus use efficiencies (PUE) in the North East China probably correspond to climates with rainfall, allowing organic matter accumulation in soil. Lower PUE and soil P accumulation (P-surplus) correspond to intensive crop production regions with high fertiliser use. The authors conclude that China crossed the Kuznets curve for phosphorus in 2007, with use efficiency improving and environmental losses decreasing since then, but that China still has one of the highest fertiliser inputs in the world, and phosphorus use efficiency relatively low, and suggest the need for regionalised policies to improve PUE and reduce agricultural phosphorus surpluses.

“Phosphorus use efficiency has crossed the turning point of the environmental kuznets curve: Opportunities and challenges for crop production in China”, W. Shen et al., J. Environmental Management 326 (2023) 116754 https://doi.org/10.1016/j.jenvman.2022.116754

Phosphorus uptake controls plant response to increased atmospheric CO2

Meta-analysis of 111 studies shows that effects of elevated carbon dioxide (eCO2) on plant biomass are best explained by plant phosphorus uptake and that eCO2 modifies aboveground biomass P pool and biomass P concentration. A literature search for paper covering both increasing CO2 and phosphorus found over 1600 papers (since 1950), of which nearly 550 were found relevant after analysis, of which 111 were retained as including data on biomass or P pools/concentrations. eCO2 showed a +13% increase in above ground biomass, but no increase in litter biomass, and to a +20% increase in above ground biomass P pool, +14% increase in biomass below ground P pool, but a decrease in above ground biomass P concentrations (+7%) and no change in below ground biomass P concentrations. Plant P uptake, which was related to biomass, was the variable which best explained increased biomass with eCO2. Effects of eCO2 on the phosphorus cycle were impacted by variables such as duration of experiment and aridity. The authors conclude that plant phosphorus uptake should be considered in future biosphere carbon dioxide modelling.

“Plant biomass responses to elevated CO2 are mediated by phosphorus uptake”, X. Han et al., Science of the Total Environment 863 (2023) 160775 http://dx.doi.org/10.1016/j.scitotenv.2022.160775

Nutrient recycling

Lex4Bio survey on “Bio-Based Fertilisers”

EU Horizon 2020 project Lex4Bio launches online survey of farmers, consumers, fertiliser producers and food & beverage industry to identify drivers and barriers to uptake of bio-based fertilisers (BBFs). The surveys, for each target sector, are online in several different languages. Depending on the target, questions cover attitudes to using waste or recycled materials to fertilise food crops, perceived safety of recycled nutrient sources, different recycled materials.

Lex4Bio surveys on bio-based fertilisers https://lnkd.in/dsB5AxFB

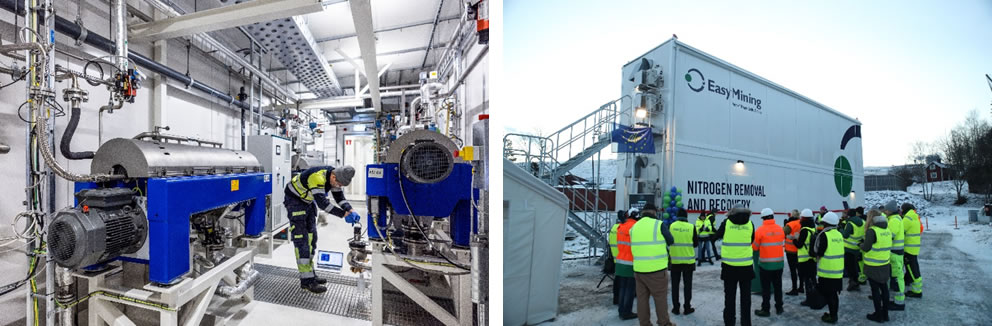

EasyMining LIFE RE-Fertilize N-recovery webinar

One-hour webinar (available online) offers detailed presentation of EasyMining’s Aqua2N nitrogen recovery process operational experience (4 m3/h) and now upscaling (10 m3/h), including Biophos’ R&D Director. The two step process removes >95% of ammonium from wastewater liquors by struvite precipitation, then dissolves the struvite in sulphuric acid, recycling the magnesium and phosphorus back to the precipitation stage, and producing ammonium sulphate solution (c. 10% solution = c. 2% N/ww, with objective to concentrate to 30 - 40% solution). Dines Thornberg, Biofos, responsible for treating Copenhagen area’s wastewater explains that the ammonium from sewage sludge digestate liquid fraction (which is returned to the sewage works) can reduce N loading to the works considerably, so increasing biological treatment capacity. Anna Lundbom, EasyMining, explains that the Aqua2N process can reduce sewage works nitrous oxide losses by 15 – 30 %, significantly reducing climate impact. Mikael Hedström, EasyMining, explains that the process is part of EasyMining’s objective to recycle resources and so mitigate climate emissions. The process has been tested, in the EU-funded LIFE RE-Fertilize project on municipal wastewater sludge liquor (Biofos Lynetten wwtp) and landfill liquor (Högbytorp) with a 4 m3/h pilot, a scale appropriate for smaller wastewater plants, enabling optimisation, and demonstrating replicability and transferability. A 10 m3/h unit for larger plants has been designed and is now entering the commercialisation phase. The recovered ammonium sulphate solution has been tested in pot trials by the Swedish Agricultural University and by farmers (Lantmännen).

Photos: EasyMining Aqua2N pilot

RE-Fertilize webinar, 26th January 2023, watch replay here: www.youtube.com/watch?v=9mbuENQsJfo

See also ESPP-DPP-NNP Nutrient Recycling Technology Catalogue http://www.phosphorusplatform.eu/techcatalogue

Implementation of German sewage P-recovery obligation

Comparison of 3 digestion and 3 analysis methods, plus interlaboratory comparison recommends ICP-OES after microwave digestion to provide reliable analysis of sewage sludge phosphorus content. 14 sludge samples from 11 different sewage works were analysed for phosphorus content using the two digestion methods and three analysis methods indicated as regards P-recovery in the German Sewage Sludge Ordinance (*): aqua regia digestion in a microwave or under reflux conditions, then inductively coupled plasma optical emission spectrometry (ICP-OES), inductively coupled plasma mass spectrometry (ICP-MS), or photometric phosphorus determination with ammonium molybdate. These methods (tested in some cases by several laboratories) showed variation of around +/- 20% in results for P-content. ICP-OES after aqua regia digestion in a microwave was identified as the most reliable method. A mixed sludge sample was analysed using these methods by 28 laboratories, showing around 7.2 % reproducibility variation in results for P content. Data show, for the sludges from these eleven wwtps, P-content of 1.7 – 3.8% and iron content of 1.4 – 5 % Fe (dry weight).

Phosphorus in sewage sludges:

Previous studies suggest similar levels of P in sewage: 0.8% - 31% (Krogstad et al. 2005), 0 - 4 % (Guivarch 2001), 2 - 6% (Frossard 1996) SCOPE Newsletter n°73, 2.6–3.4% (Cydzik‑Kwiatkowska & Nosek 2020), 3.4 % (Phong 2022), 4.3% (Falk 2020).

The European Commission seminar of 1980 indicated P-content of sewage sludges:

- For Switzerland, increase from 1.1 % P/dm in 1971 to average of 2.7 % P/dm in 1979: (0.2 - 4.6 % in wwtp without P removal and 0.9 - 7.9 % in wwtp with P-removal). The increase is considered to be due to implementation of P-removal.

- For Belgium (Wallonia), 0.2 – 0.9 % P/dm

- For Finland, 2 – 3.7% P/dm for chemical P-removal sludge

* German sewage P-recovery Ordinance: AbfKlärV 2017 German sewage sludge directive (Verordnung zur Neuordnung der Klärschlammverwertung) LINK

“Determination of the phosphorus content in sewage sludge: comparison of different aqua regia digestion methods and ICP‑OES, ICP‑MS, and photometric determination”, T. Sichler et al., Environmental Sciences Europe (2022) 34:99 LINK.

See also Sichler et al. in ESPP eNews n°66.

Phosphorus in sewage sludge incineration ash (SSIA) is not short-term plant available

Ashes from four German sewage sludge incinerators were tested as phosphorus fertilisers in 4-week pot trials, showing considerably lower P Use Efficiency than mineral P fertiliser (MCP) and similar or worse than phosphate rock in these short-duration tests. Pot trials used the P-sensitive flowering plant Tagetes patula (French marigold) with soil pH of 6 or 4.5 with weekly applications of P fertiliser/ash and of nitrogen as required. Particle size distribution of the ashes was recorded. Phosphorus Use Efficiency was calculated based on P uptake. At soil pH 4.5 plant fresh weight was similar with the sludge ashes compared to MCP (water soluble P fertiliser) or phosphate rock, whereas at pH 6 fresh weight was significantly higher with ash than with phosphate rock, but lower than with MCP. Plant P uptake and P Use Efficiency was significantly lower than for MCP at both soil pHs, and was four times lower at soil pH 6. The authors note that phosphorus solubility test methods with calcium chloride + diethylenetriaminepentaacetate (CAT) and calcium-acetate-lactate (CAL), as widely used in Germany, do not give useful predictions of plant P availability in sewage sludge incineration ash.

“Phosphorus Availability from German Sewage Sludge Ashes to Plants Cultivated in Soilless Growing Media of Contrasting pH”, D. Hauck et al., Agronomy 2022, 12, 2610 DOI.

Phosphorus uptake from nine secondary materials and P extraction methods

Phosphorus efficiency of struvite in pot trials was the same or better than mineral P fertiliser, but was considerably lower for an iron phosphate containing sewage sludge and for two sewage sludge ashes.

In papers 2021 and 2022-1, RAE (relative agronomic efficiency) of phosphorus in secondary materials was compared to mineral phosphate fertiliser (TSP = triple super phosphate) and no phosphate (control) in seven month pot trials with perennial ryegrass at three P dose levels (one application at start):

- Two different struvites, both recovered from sewage, both c. 8% P, C-org < 0.5%,

- Dried pelletised sewage sludge from a sewage works, 0.8% P, 16 % C-org, 2% Fe

- ASH1: ash from sewage sludge from a rotary kiln process, 900-1000°C with sodium sulphate additive, 6% P, low C-org, 4.4% Fe

- ASH2: ash from sewage sludge from a two-step rotary kiln process (pyrolysis 650-750°C then incineration 900-1100°C, without chemical additives at this stage of the technology development), c. 6% P, c. 8% C-org and 16% Fe.

The first paper (2021) compares the phosphorus fertiliser effectiveness of the five secondary materials to TSP. At 9 and 19 kgP/ha, after one month, one of the two struvites showed phosphorus fertiliser efficiency (RAE relative agronomic efficiency) similar to mineral fertiliser (Fig 3). The other struvite, the two ash materials and the sewage sludge pellets showed considerably lower RAE after one month. However, RAEs were similar after one month at 28 kgP/ha application (except for ASH2 which was much lower). After four months the two struvites showed RAEs similar to mineral P fertiliser. After seven months, the RAEs of the two struvites were > 110% (better than TSP), whereas the two ashes and sludge pellets showed RAEs of below 75% at 9 and 19 kgP/ha and 30 - 84 % at 28 kgP/ha.

A second paper (2022-1), based on the same pot trial data, compares P measured by eleven different extraction methods, ranging from strong acid “destructive” total-P to Olsen-P, to shoot P uptake in seven cuts from one to seven months. This shows (table S11) that, for these six materials (two struvites, dried FeP sludge, two ash materials, TSP) and for cumulative P uptake after seven months, only six extraction methods showed correlation > 0.6 (in order of highest correlation: 2% citric acid, microwave digestion + nitric acid, nitric acid, ammonium lactate, NAC = neutral ammonium citrate, microwave digestion + aqua regia) whereas (table 4) five showed correlation < 0.5 (Mehlich3, Bray 2, water, calcium chloride and Olsen-P). However, all extraction methods showed correlation for P uptake after seven months > 0.6 if the mineral fertiliser TSP was excluded. After only one month, six methods showed correlation > 0.6 to shoot P uptake (in order: water, calcium chloride, NAC, Mehlich3, microwave + nitric, ammonium lactate).

The third paper (2022-2) shows results of 4-month pot trials with perennial ryegrass for Euphore output ash (two-step rotary kiln process without chemical additives at this stage of the technology development, see ESPP-DPP-NNP Technology Catalogue), iron phosphate extracted from sewage sludge, crab carapace material and microalgae, in three different substrates (compared to TSP and control), concluding that four months were needed for P from these materials to become plant available.

2021: “Impact of time and phosphorus application rate on phosphorus bioavailability and efficiency of secondary fertilizers recovered from municipal wastewater”, Chemosphere 282 (2021) 131017 https://doi.org/10.1016/j.chemosphere.2021.131017

2022-1:“Phosphorus Availability in Recycled Fertilizers: Comparison of 11 Chemical Extraction Methods with Plant Uptake During a 7‑Month Growth Experiment”, A. Bogdan et al., J. Soil Science and Plant Nutrition 2022 https://doi.org/10.1007/s42729-022-01075-5

2022-2: “Substrate-Driven Phosphorus Bioavailability Dynamics of Novel Inorganic and Organic Fertilizing Products Recovered from Municipal Wastewater - Tests with Ryegrass”, A. Bogdan et al., Agronomy 2022, 12, 292. https://doi.org/10.3390/agronomy12020292

Freeze concentration to concentrate digestate RO liquor

Progressive and suspension freeze concentration (FC) were tested at lab scale to concentrate the nutrients from a membrane filtrate (ultrafiltration + reverse osmosis RO) liquor from pig slurry and agro-industrial waste digestate, from an anaerobic digester in Catalonia, Spain. The RO process, operating on the liquid fraction of solid-liquid separated digestate, gives clean effluent water which can be discharged and a nutrient “concentrate” (1%N, 0.02%P, 2%K). Freeze concentration was tested in 2 litre lab reactors with circulating refrigerant at -5, -10 and -15°C with the aim to further concentrate the nutrients present in the RO “concentrate”. After two hours of freeze concentration, around 56 % of N, 90 % of P and 63 % of K was concentrated in the liquid fraction (50% of the initial volume), that is phosphorus concentration was nearly doubled by the freeze drying whereas N and K concentration not increased by more than 20%. In an earlier paper, the same authors tested multi-stage progressive freeze concentration in the same 2 litre lab reactor on cheese whey from a dairy processing factory, achieving 2 – 3 x increases in lactose and protein contents after 2 – 4 freeze concentration cycles. Further studies underway, but not published yet, assess the freeze concentration technology at a pilot scale using a 40-litre reactor tested with digestate (in the Fertimanure Horizon 2020 project). The authors conclude that freeze concentration has a similar or lower operational energy consumption than membrane concentration technologies and offers significant energy-saving potential compared to thermal and evaporation processes.

“Application of Freeze Concentration Technologies to Valorize Nutrient-Rich Effluents Generated from the Anaerobic Digestion of Agro-Industrial Wastes”, I. Uald-lamkaddam et al., Sustainability 2021, 13, 13769. https://doi.org/10.3390/su132413769

“Progressive freeze concentration of cheese whey for protein and lactose recovery”, I.Uald Lamkaddam et al., International Dairy Journal 139 (2023) 105572 https://doi.org/10.1016/j.idairyj.2022.105572

Stay informed

SCOPE Newsletter: www.phosphorusplatform.eu/SCOPEnewsletter

eNews newsletter: www.phosphorusplatform.eu/eNewshome

If you do not already receive ESPP’s SCOPE Newsletter and eNews (same emailing list), subscribe at www.phosphorusplatform.eu/subscribe

LinkedIn: https://www.linkedin.com/company/phosphorusplatform

Slideshare presentations: https://www.slideshare.net/phosphorusplatform

Twitter: @phosphorusESPP

YouTube https://www.youtube.com/user/phosphorusplatform

ESPP members