Process & contact

https://terranova-energy.com/umweltschutz/

Contact:

Member of DPP

Updated 09/24

Input materials

Raw or digested sludge after dewatering, from WWTPs operating biological and/or chemical P-removal.

Output products

P2O5 15% of which 90% is NAC soluble

Ca: 2 – 6 %

Contaminants:

Process description

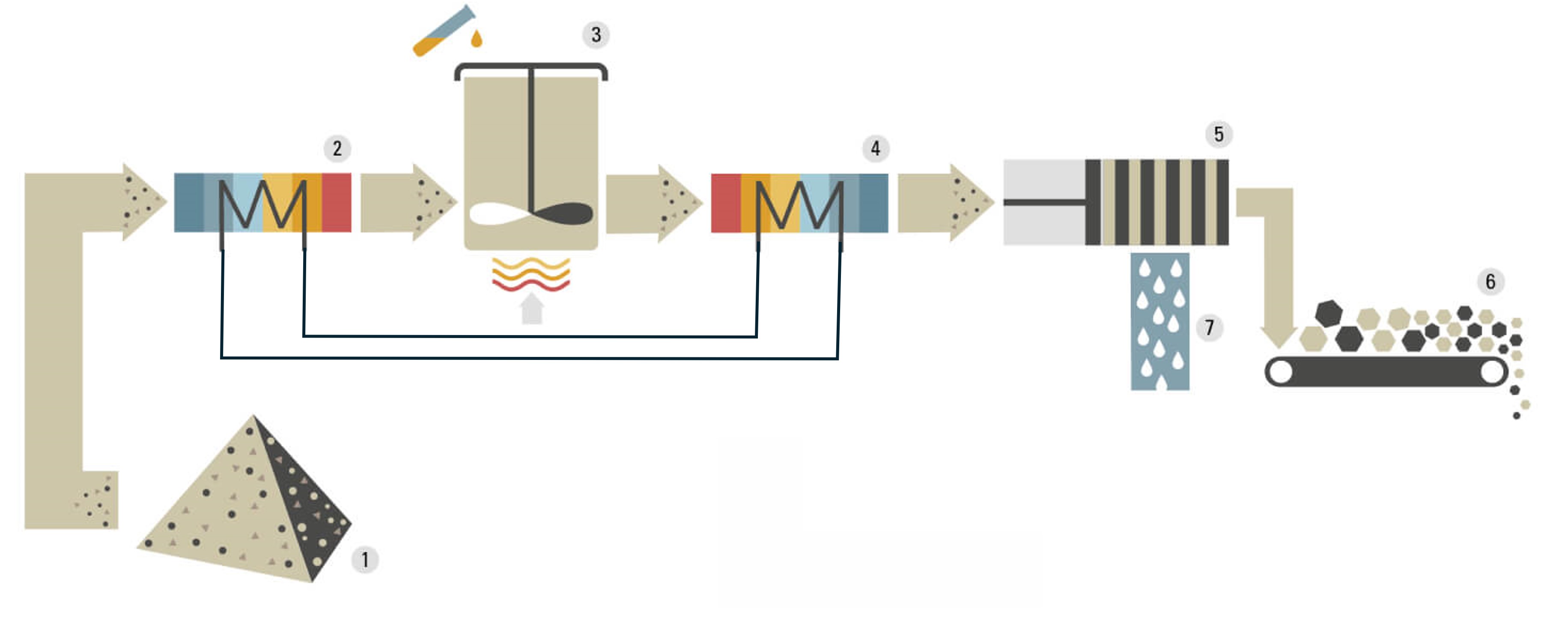

1. Dewatered sewage sludge (1) with a dry matter content of 5-30% is fed into the input heat exchanger (2) by means of a high-pressure pump.

2. The preheated sludges is hydrolysed in a stirred reactor (3) with addition of catalysts at approx. 170°C for about 5 hours. The stirred reactor is jacket-heated by a thermal oil circuit. The heat source can be, for example, the exhaust gas heat of a combined heat and power plant.

3. The resulting hydrolysed slurry is cooled down by means of an output heat exchanger (4). The heat energy extracted in the process is fed back to the input heat exchanger (2) via a separate thermal oil circuit.

4. After the output heat exchanger (4) the slurry's pH level is decreased by adding mineral or organic acid. This causes leaching of phosphorous from Fe- or Al- components generated in the upstream waste water treatment process, into the liquid phase. More than 80% of the sewage sludge phosphorous is released.

5. In a dewatering unit, for example a fully automated chamber filter press, the sludge solids are separated (5). A dosing step adds Calcium-Silicate-Hydrate granulates (CSH) to the phosphorous-rich filtrate (7). The dissolved phosphorous adsorbs at the CSH granulates, which are separated in a secondary downstream filtration step. The use of CSH allows the choice of particle size, which allows easier solid-liquid separation compated to e.g. the use of lime as precipitant. The silica component of CSH remains in the precipitate.

6. The remaining phosphorous-depleted solids can be used as fuel for incineration, thanks to the low water content between 35% and 10%

Operating status

Full scale plant operating on dewatered sewage sludge in China (since 2016); input capacity 2 t/h

Demonstration plant at Ruhrverband/Duisburg Germany, input capacity 250 kg/h.

Demonstration plant at San Rocco/Milano Italy, input capacity 250 kg/h (2022).