Process & contact

Fertibox

Verona University

Prof. Nicola Frison,

Prof. Federico Battista,

Prof. David Bolzonella,

Input materials

Anaerobic digestate (agricultural digestate, OFMSW digestate) and anaerobic fermentates

Output products

i) RO retentate rich in ammonium and potassium compounds for application as soli amendment

ii) an organic fraction containing phosphate

iiI) ammonium sulphate (optionally)

Process description

The core of the process consists of three sequential filtration steps: mechanical separation, ultrafiltration (UF), and reverse osmosis (RO).

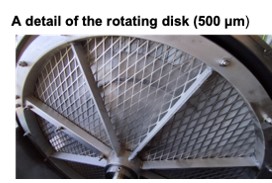

The mechanical separation step employs two rotating parallel disks equipped with a 500 µm mesh. This step yields a fine (<100 µm) solid fraction rich in fibers, organic carbon, nitrogen, and phosphorus, ready for further processing in the UF module. This utilizes columns of ceramic membranes at 4 bars pressure difference. The UF retentate is enriched with phosphorus, organics, and mineral nitrogen, while the UF permeate progresses to the final RO stage at 70 bars. Its output is 50% (w/w) of water from the raw anaerobic digestate. This step produces a concentrated product rich in ammonium and potassium compounds, which can be directly applied as a valuable soil amendment.

Optionally, the UF permeate or the RO retentate can be fed to a membrane contactor module in order to obtain ammonium sulphate and valorised as mineral fertilizer.

Operating status

TRL 7; up to 20 tons/d of anaerobic digestate