Newsletter about nutrient stewardship - European Sustainable Phosphorus Platform (ESPP)

Please subscribe www.phosphorusplatform.eu/Subscribe

Link to www.phosphorusplatform.eu/eNews075

Download as PDF

White Ammonia – Nitrogen Recovery

1st White Ammonia Research Meeting (WARM) - 7th June 2023

EU public consultations

EU draft update of Slaughterhouse BAT BREF

EU public consultation on “Taxonomy”: green investment funding

EU public consultation on fertiliser digital labelling

EU public consultation on Critical Raw Materials

EU input needed – recycled fertiliser products

Input on processing of manure products

Comments on proposed analysis standards for STRUBIAS materials

Animal By-Products (ABPs) in EU Fertilising Products Regulation delayed again

Policy

European Commission document on Food Security

European Parliament position on fertilisers

Updated EU Regulation on agricultural statistics (SAIO)

European Environment Agency report on soil monitoring

Nutrient recovery inauguration

Inauguration of Ragn-Sells - EasyMining first Ash2Salt plant 5

Research and development

Ammonia losses to air from livestock and combustion

Black soldier fly for wastewater resource recycling

Overview of agricultural P loss challenges

Benefits of Legacy Phosphorus

Stay informed

ESPP members

White Ammonia – Nitrogen Recovery

1st White Ammonia Research Meeting (WARM) - 7th June 2023

ESPP is organising a first White Ammonia and N-recovery Research Meeting (WARM) in Brussels and hybrid, Wed. 7th June 2023 (plus nitrogen recovery site visit 6th June). This will showcase research and innovation into nitrogen recovery and make links from EU R&D policy to industry implementation. Confirmed presentations to date include: European Commission DG Research and DG Environment, Fertilizers Europe, Severn Trent and ACEA.

This is within EU Green Week, Brussels, and back-to-back to the 6th Power to Ammonia Conference by NH3 Event, Europe’s biggest ammonia event, Rotterdam 8-9 June 2023 (one hour train from Brussels).

Proposals for presentations or posters are welcome:

Registration is now open: http://www.phosphorusplatform.eu/events

EU public consultations

EU draft update of Slaughterhouse BAT BREF

Draft update of EU BAT BREF for Slaughterhouse & Animal By-Product and Co-Product Industries is published. Public comments are invited. IED (Industrial Emissions Directive) Forum members (includes ESPP) are invited to input comments by 11th May latest, so please send any comments to ESPP by 8th May. The 540 document is a proposed update of the existing 2005 BAT BREF. Techniques presented as BAT (Best Available Technology) include: phosphorus recovery as struvite for resource recovery ($2.3.2.7 page 96) and wastewater treatment ($2.3.6.5.3 page 157) and in BAT12 and BAT14 (for wastewaters with Ptotal > 50 mg/l, $5.1.6 and $5.1.7 pages 450-451); P-removal from wastewater by chemical precipitation or enhanced biological P-removal (EBPR); dicalcium phosphate manufacture from gelatine production ($4.5.2.2 page 427); anaerobic digestion with use of digestates as N, P, K containing fertiliser ($2.1.2 page 31). It is indicated page 378 that wastewater treatment sludge can be sent to incineration then P-recovery. Total phosphorus and total nitrogen emissions to water are KEIs (Key Environmental Indicators, p.25). Use of sludge from gelatine production, feathermeal, PAP processed animal proteins or blood byproducts directly on farmland as a fertilising material are cited (pages 354, 369, 374, 433). Ammonia N-recovery from rendering condensate is cited ($4.3.4.2.2 page 397). BAT14 specifies limits (for direct discharge) of 4 – 30 mg/l for Ntotal and 0.25 – 2 mg/l for Ptotal – ESPP suggests that these limits seem non-ambitious compared to limits widely applicable to municipal wastewater treatment plants. ESPP will input comments to propose to add to BAT1 (Overall Environmental Performance) a nutrient valorisation plan, conform to the waste hierarchy (food, feed, fertiliser). ESPP will also comment that anaerobic digestion should ensure Animal By-Product Regulation 142/2011 End-Point heat/time conditions, to ensure sanitisation, and to enable use of digestates as fertiliser.

Draft “Best Available Techniques (BAT) Reference Document for the Slaughterhouses, Animal By-products and/or Edible Co-products Industries”, proposed update of existing 2005 BREF http://eippcb.jrc.ec.europa.eu/reference/ Comments to ESPP by 8th may.

EU public consultation on “Taxonomy”: green investment funding

Consultation open to 3rd May 2023 for EU Taxonomy Regulation, defining technologies eligible for green investment funding (and possibly by extension other support or policy tools): includes P-recycling from municipal wastewater (Annex II = contribution to the circular economy, § 2.1). The draft Delegated Regulation will be adopted by the European Commission after the public consultation period and internal concertation, and does not go to the European Parliament and Council. The proposed Regulation and Annexes are based on the initial reports published by the European Commission in 2021 and 2022, see ESPP eNews n°s 59 and 66. Some of ESPP’s comments on the first draft are taken into account (clarifications regarding recovery routes, inclusion of end-uses other than in fertilisers, requirement of end-product to have a use …). The criteria require that at least 15% of incoming phosphorus is recovered for processes at the waste water treatment plant, and at least 80% for processes treating sewage sludge ashes.

ESPP continues to regret that recovery of nitrogen or of other nutrients is not included, that the wording is likely to exclude some processes for processing P in sewage sludge to organic fertilisers (e.g. biochars), and that the criteria cover only phosphorus recycling from “waste water treatment plants” not from e.g. manure*.

The proposed Regulation also includes, amongst many other sectors, with specified conditions:

- treatment of separately collected bio-waste through anaerobic digestion or composting with the resulting production and utilisation of biogas, digestate, compost or chemicals (Annex II – 2.5);

- urban waste water treatment systems (Annex I – 2.2);

- mechanical material recovery form non-hazardous waste (Annex II – 2.7). This does not cover chemical recovery of e.g. potassium from waste-to-energy combustion ashes, however the preamble (14) states that recovery of “metals and inorganic salts from … ashes from non-hazardous waste incineration” should be considered for inclusion in the next update of the Taxonomy criteria.

Unlike the initial Commission report, the proposed Regulation does not cover agriculture.

* The draft text refers to “recovery of phosphorus from on-site waste water treatment plants (WWTP) (aqueous phase and sludge) and from materials (i.e. ashes) after thermal oxidation (i.e. incineration) of sewage sludge”. It is unclear what this means. On the one hand, the text later refers to “sewage sludge”, but on the other hand it cites NACE codes “in particular” E37.00 = sewerage, E38.32 = does not exist (maybe should read E38.3.2 - Recovery of sorted materials ?) and F42.99 = does not exist (maybe should read F42.9.9 - Construction of other civil engineering projects n.e.c.).

“Sustainable investment – EU environmental taxonomy”, EU public consultation to 3rd May 2023 and draft Delegated Regulation establishing further Technical Screening Criteria for the EU ‘Taxonomy’ Regulation 2020/852 HERE.

See also: European Commission taxonomy and sustainable finance web page HERE and EU Taxonomy Navigator online tool HERE.

EU public consultation on fertiliser digital labelling

Consultation open to 29th May 2023 on draft amendments to the EU Fertilising Products Regulation (FPR) to enable digital labelling of EU fertilising products before discussion in EU Parliament and Council. The proposed amending Regulation modifies both articles of the FPR itself and of its annexes. Modifications enable obligatory labelling information to be provided by digital means and specify functioning of this, and also modify definitions of packaging and labelling requirements, in some cases, for labelling soluble content of nutrients, organic carbon, dry matter, micronutrients, pH and stability ranges …

Proposal for a regulation COM(2023)98. Consultation open to 29th May HERE.

EU public consultation on Critical Raw Materials

Consultation extended to 19th June 2023 on draft EU Critical Raw Materials Regulation, before discussion in EU Parliament and Council, covering Critical and Strategic Raw Materials Lists, with update of the EU Critical Raw Materials List, including phosphate rock and P4 – details in ESPP eNews n°74 and Consultation here (4000 characters free text plus optional document).

EU input needed – recycled fertiliser products

Input on processing of manure products

The European Commission (DG GROW) is preparing criteria for use of hygienised manure materials in EU fertilisers, and looks for input to define what “post processing” methods to include in CMC10. The DG SANTE delegated act authorising the use of certain hygienised manure materials in EU fertilisers (defining an ABP End-Point “processed manure” as defined in the Animal By-Products Regulations) is now nearly finalised and may be published in coming months. The European Commission (DG GROW) will then prepare a modification to the EU Fertilising Products Regulation (FPR) to specify the inclusion of such “processed manure” in EU-fertilisers (in CMC10), see below. “Processed manure” here means manure which has been hygienised using the “standard methods” defined in the Animal By-Products (ABP) Regulation 142/2011, Annex XI, Chapter I, Section 2 (a), (b), (d) and (e). However, under the EU FPR, a CMC material can only be used in, or as, a fertilising product if there is no further treatment or processing. It is therefore important that the future CMC10 criteria for hygienised manure materials (ABP “processed manure”) specify the treatments which can be carried out (after the ABP hygienisation) for its use in fertilisers. Such treatments could include drying, granulation, solid-liquid separation, stabilisation, pH adjustment, possibly with additives to be specified necessary for such processes. Please send to ESPP specifications of treatments you suggest are relevant for hygienised manure (ABP “processed manure”) and which you suggest should be included in CMC10.

Input by email by 10th May to ESPP

Comments on proposed analysis standards for STRUBIAS materials

The European Commission has circulated for comment a proposed mandate to CEN to develop some 30 new analysis standards for CMCs 11 – 15, that is by-products, STRUBIAS and recovered mineral materials, including precipitated phosphates, ash-based materials, pyrolysis/gasification materials. Proposed standards include methods for determination, in these materials where relevant for EU Fertilising Products Regulation criteria, of levels of phosphate, iron, other elements, organic carbon, H / Corg, macroscopic impurities, PAH16, PCDD/F, pathogens and of hygienisation conditions (temperature, time).

Commission draft standards mandate here (for new proposed standards for STRUBIAS, by-products, recovered minerals) see Annex II, page 29 onwards). Comments by 10th May to ESPP

Animal By-Products (ABPs) in EU Fertilising Products Regulation delayed again

The European Commission informed the Fertilisers Expert Group, 18th April, that inclusion of “processed manure” into the EU Fertilising Products Regulation is delayed to at least end 2023 and other ABPs to at least end 2024. This is because environmental safety assessments are legally required. This concerns the Animal By-Products covered by the draft DG SANTE delegated act defining “End Points” for use in EU fertilisers (see ESPP eNews n°70). The Commission confirmed that manure (and other specified Cat. 2 and 3 ABPs) will however be authorised as input materials to EU fertilising product composts, digestates, precipitated phosphates, ash-based materials and pyrolysis materials (CMCs 3, 5, 12, 13, 14) as soon as the DG SANTE delegated act enters into force. It is ESPP’s understanding that this will mean that for these CMCs will be able to include manure / specified ABPs either (i) if these have been hygienised (by ABP ‘standard methods’: Regulation 142/2011) BEFORE entering the composting / digestion / combustion / pyrolysis process or (ii) raw manure / specified ABPs is input into the composting / digestion / combustion / pyrolysis process and this process itself respects the ABP “standard methods” obligations. ESPP will ask that this be clarified in the EU FPR Frequently Asked Questions document after the DG SANTE delegated act is published.

Policy

European Commission document on Food Security

EU communication on Food Security reminds that the EU is largely food self-sufficient but that food inflation is nearly 20%/year. Fertilisers supply and price accentuates other pressures reducing agricultural productivity: climate change, loss of pollinators, labour shortages … 61% of agricultural land is arable (and more than half of this is to produce animal feed), and 31% of agricultural land is grassland. Ecosystem contribution to crop yield values is estimated to be 21%, with the remainder resulting from human inputs (planting, labour, chemicals). Agriculture is the main source of nitrogen discharge to waters and contributes to eutrophication, and contributes over 10% of EU greenhouse emissions (over 2/3 of this related to livestock). The 100 page Communication discusses a wide range of drivers of food security including climate, pollution, soil health, pests and diseases, biodiversity, research and technology, production intensity, trade, speculation, energy prices, fertilisers, workers, economics and finances, land use, supply chain, food loss and waste and demography. Mineral fertilisers are considered to “play a significant role for food security”, but (nitrogen) fertiliser prices are directly connected to energy prices and the EU is largely dependent on fertiliser imports. The EU is estimated to be around 30% dependent on imports for N fertilisers, 68% for P and 85% for K. High energy prices risk increasing these dependencies. Increased fertiliser prices lead farmers to apply less, resulting in lower yields and impacting food availability and access. Nutrient management plans, soil conservation, precision agriculture, crop rotation with legumes and nutrient recycling are cited as mitigating pressure from high fertiliser prices. For the fertiliser industry, a “green transition” is considered critical, using green hydrogen, digestate and compost, with improved nutrient use efficiency and so lower nutrient losses to the environment.

“Drivers of Food Security”, European Commission SWD(2023)4, 4th January 2023 https://commission.europa.eu/publications/analysis-main-drivers-food-security_en

European Parliament position on fertilisers

Parliament resolution supports development of organic and recycled fertilisers, underlines negative impacts of fertiliser prices on farmers, supports livestock farming and calls to increase the EU farm budget (CAP). The position notes that phosphorus and nitrogen exceed planetary boundaries in the EU, but also calls for increased regional flexibility to exempt from Nitrates Directive nitrogen application limits and for the “presence of livestock on most territories” for “a more uniform availability of organic fertilisers”. Parliament calls to amend the Nitrates Directive and to enable “temporary derogations” for RENURE materials and digestates. Parliament notes that many secondary nutrient sources are not optimally used, calls for Member States’ CAP Strategic Plans to stimulate development of organic fertilisers and for actions, including investments and business plans, to support and improve market access for organic and recycled fertilisers, as well as crop rotation with plants which fix nitrogen, nutrient use efficiency and precision farming. Parliament calls for implementation and upscaling of the Farm Sustainability Tool for Nutrients (FaST) to develop nutrient balances for farms.

Availability of fertilisers in the EU”, European Parliament resolution 16th February 2023, “P9_TA(2023)0059 https://www.europarl.europa.eu/doceo/document/TA-9-2023-0059_EN.html

Updated EU Regulation on agricultural statistics (SAIO)

New Regulation requires reporting of all fertilising products (as defined by the EU Fertilising Products Regulation), and of both nutrients used in fertilisers and nutrient balances. Member States will be required to report average fertiliser purchase prices for different fertiliser products, nutrients in fertilising products and nutrient balances, at either the national or regional NUTS2 level (to be defined by the European Commission), and covering 95% of the Member State agricultural area. Data on nine different parameters relevant to calculating national nutrient balances will be required: inorganic fertilisers, organic fertilisers (excluding animal manure), crop and forage nutrient contents, crop residues and nutrient coefficients, biological N fixation coefficients, atmospheric N deposition coefficients, seed nutrient content coefficients, livestock manure volumes and nutrient content coefficients.

(Amending) Regulation (EU) 2022/2379 on “statistics on agricultural input and output”, 23 November 2022, HERE.

European Environment Agency report on soil monitoring

EEA 200 page report proposes soil health indicators including parameters for phosphorus and nitrogen to ensure that low levels do not compromise productivity but also to limit nutrient losses. Chapter 3 on soil nutrient loss (phosphorus and nitrogen) underlines and explains the concept of “critical” phosphorus levels for crop yield, below which yields will be reduced, and above which additional phosphorus input makes little difference, but which may be different from the critical level for phosphorus losses, above which losses increase rapidly with higher inputs. The following soil health indicators and monitoring parameters are proposed for phosphorus and nitrogen (in combination with parameters including organic carbon, pH, contaminants, soil compression …):

- Falling below of optimal phosphorus

- P limitation based on exceedance of N:P ratio

- Exceedance of critical levels of mineral nitrogen

- N limitation based on exceedance of C:N ratio

- Total (organic) nitrogen

- C:N ratio

- Total N

- Mineral N

- Total P

- Available P: Pox/Al+Feox

- Available K

Threshold levels are proposed for contaminants, but not for nutrients.

“Soil monitoring in Europe — Indicators and thresholds for soil health assessments”, European Environment Agency EEA Report No 08/2022 https://www.eea.europa.eu/publications/soil-monitoring-in-europe and DOI

Nutrient recovery inauguration

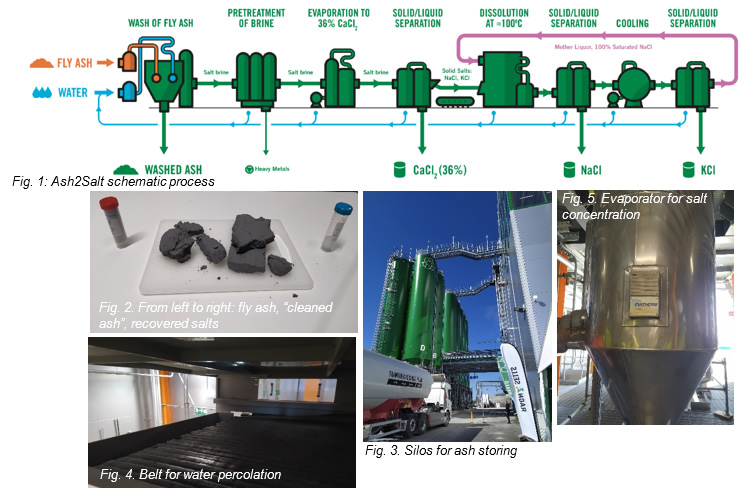

Inauguration of Ragn-Sells - EasyMining first Ash2Salt plant

The first commercial facility recovering potassium, calcium and sodium salts from municipal waste incineration fly ash was inaugurated in Högbytorp, Sweden by the Swedish Minister of Climate and Environment, Romina Pourmokhtari, alongside Erik Sellberg, Chairman of Ragn-Sells Board. The Minister emphasised Sweden’s commitment to achieving Net Zero Emissions by 2045, that transitioning to a circular economy is crucial to achieving this goal, and underlined the role of active companies prioritising sustainable development. Pär Larshans (Director of Sustainability at Ragn-Sells) then led a panel discussion with Anette Blücher from EON/Nordic, Emma Nohrén from the Swedish Parliament, Ellen Einebrant from The Recycling Industries, and Mattias Peterson Ersoy from Upplands-Bro Municipality. The panel stressed the importance of industrial symbiosis in achieving the environmental targets, and the need to shift away from the current paradigm of waste plants towards that of resource plants.

Fly ash is a waste product generated during the cleaning of flue gases in municipal waste incineration plants. Due to its high content of salts (200 kg per ton of ash) and heavy metals, it is classified as hazardous waste. In Sweden alone, 300 000 tons of fly ash are produced annually. The Ash2Salt process allows the recovery of the salts (potassium, calcium, and sodium chloride) present in fly ash (Fig. 1,2). The inaugurated plant, which cost 70 million €, can treat up to 150 000 tons of fly ash per year, producing roughly 10 000-12 000 tons of NaCl (solid), 6 000 tons of KCl (solid), and 25 000 tons of CaCl2 (saturated solution (36%) per year. The fly ash is received from 15 Swedish incineration and waste-to-energy plants, and is loaded into silos on the plant roof from ten 180 m3 silos on the side of the plant (Fig. 3), as shown by Mattias Lindblad, Head of Production at the Ash2Salt plant. The ash is then dropped to vessels and mixed with water using propeller agitators, to dissolve the salts. After this, the ash is passed onto a belt (Fig. 4), allowing the water containing the salts and heavy metals to percolate through, leaving a "washed ash" or "cleaned ash" that can be deposited at a landfill for non-hazardous waste. Some research is underway to find alternative uses for the washed ash, while the cleaning water coming out of the filter, containing the salts and heavy metals, is treated to remove heavy metals (through precipitation and separation). Additionally, organics are removed through a carbon filter. An evaporator is used to increase the concentration of salts in the cleaning water, which can process 20 m3 of water per hour (Fig. 5). Once the solution becomes saturated in CaCl2, NaCl and KCl begin to crystallize and are separated based on their different properties. This process leaves behind a 36% CaCl2 solution, while ammonia released during the evaporation process is scrubbed out to (NH4)2SO4. The recovered salts can be used for various purposes, including fertilisers (KCl, (NH4)2SO4), dust control and deicing (CaCl2), or other industrial processes (NaCl, KCl).

The inauguration event was preceded by a visit to EasyMining's R&D facilities in Uppsala. During the visit, Jan Svärd (CEO) and Yariv Cohen (Head of Research and Development) presented EasyMining’s Ash2Phos and Aqua2N technologies (see eNews 62 and 74, respectively), and Michael Pohl (Head of Research and Development, Omya) presented new approaches for Zero Liquid Discharge, including the Brine2Mineral project collaboration, which aims to remove Mg and Ca from brine effluent in the Ash2Phos process.

Research and development

Ammonia losses to air from livestock and combustion

Isotopic analysis distinguishes ammonia air emissions from agriculture from combustion emissions, suggesting that around half are in Europe are from farming (fertilisers, animal wastes) and around half from combustion. The authors distinguish “v” ammonia emissions to air (volatilisation from fertilisers, fertilised and natural soils, animal wastes, water) from “c” emissions (combustion of fossil fuels or biomass). The authors compared the data for different N-isotopes in the ambient atmosphere (a), atmospheric particulates (p) and precipitation (w) for East Asia, Europe and North America. Comparison of ratios enables estimation of volatilised ammonia “v” (assumed by the authors to be mainly related to agriculture) and combustion ammonia “c”. They conclude that around 51%, 54% and 60% of ammonia losses to air are from volatilisation “v” in Europe, North America and East Asia respectively, but with margins of error of +/- 20%. They thus conclude that ammonia emissions are generally significantly underestimated.

“Significant contributions of combustion related sources to ammonia emissions”, Z-L. Chen et al., Nature Communications (2022) 13:7710, DOI.

Black soldier fly for wastewater resource recycling

Innovative process (patented) enables cultivation of black soldier fly (BSF) larvae in liquid, so coupling treatment of high organic carbon wastewaters and valorisation of nutrients and carbon. BSF are already commercially cultivated on solid organic wastes, to produce proteins, lipids, aquaculture feed and organic fertilisers (see Protix at SOFIE2). The fly larvae cannot normally survive in a liquid medium. The patented process overcome this by providing an inert physical support for larvae mobility: diving for eating and re-emerging for breathing. The process has been successfully tested to date at lab scale (0.15 l, 180 cm2 surface area) using synthetic wastewaters and real wastewaters, including food processing wastewaters, landfill leachate. This suggests that the larvae need at a minimum organic carbon level in the feed wastewater to ensure sufficient food. Results (not yet published) suggest that the larvae system can remove c. 80% of nitrogen and 50% of phosphorus from waste water with initial levels c. 150 mgN/ and 16 mgP/l. After depletion of carbon and nutrients in the wastewater by the fly larvae, treatment can be completed with conventional technologies, while larvae are separated and recovered.

“The treatment of leachate using Black Soldier Fly (BSF) larvae: Adaptability and resource recovery testing”, V. Grossule et al., 2020, J. Environ. Manage. 253, 109707, DOI.

“Treatment of wastewater using black soldier fly larvae , under different degrees of biodegradability and oxidation of organic content”, V. Grossule et al., 2022, J. Environ. Manage. 319, 115734, DOI.

“Treatment of wastewater using Black Soldier Fly larvae: Effect of organic concentration and load”, V. Grossule et al., 2023, J. Environ. Manage. 338, 117775, DOI.

Overview of agricultural P loss challenges

8-page layperson’s summary update article explains farm P-losses are today key to surface water quality problems (eutrophication), discusses challenges of soil Legacy-P and possible solutions. Agricultural phosphorus losses are today the main cause of major eutrophication problems in the US/Canada Great Lakes, the Mexico Gulf Dead Zone and in many other lakes in North America, because wastewater treatment plant discharges have been now mostly addressed. At the same time, uptake of applied phosphorus in the first crop season is <20% global average and P-losses linked to soil erosion are a major route for phosphorus resource depletion (Alewell et al., 2020). The challenge is that P applied tends to bind in soils, so is not readily crop available, whereas many crops need P rapidly (e.g. half of maize’s P requirement is after flowering). But when P is applied up to levels such that it is readily available, then it tends to be lost in surface runoff or drainage with rainfall. On the other hand, P applied in the past and bound in soil (Legacy-P) slowly becomes available, so can contribute to today’s P-losses. Illinois, an intensive agriculture State, has a negative P balance over recent decades, but P losses continue as soil Legacy-P shows a “lag time”. Solutions discussed include not only appropriate P application (fertiliser, manure …), but also improving soil P testing and linked P application recommendations, phosphorus trap using specific underground filter structures, streambank buffer vegetation, cover crops, biostimulants to improve crop P uptake and fertilisers which release P according to plant needs (e.g. struvite).

“Blue Waters, Green Fields. Going Beyond BMPs and 4Rs to Control Future Phosphorus Loss to the Environment”, S. Windsor, Crops & Soils Magazine (American Soc. Agronomy) Jan-Feb 2023 DOI.

Benefits of Legacy Phosphorus

Incubation and pot trials demonstrate how P accumulated in soil, by long-term P fertilisation, improves effectiveness of further P-fertiliser application for crops, and underlines need to consider buffering capacity in soil P testing. Soil with different levels of “Legacy-P” was simulated by incubating low-P soil, with high buffering capacity, from West Bengal, India, at 70°C for 30 days in soluble P solutions 0 – 5000 mgP/kg soil. This is estimated to be equivalent to five years at 20°C. A second incubation in 0 – 1000 mgP/kg soil showed no further modification of P levels in the simulated Legacy-P soils, indicating that P had stably reacted with the soil. The five legacy P soils showed increases of Olsen-P up to nearly 2000 mg/kg (then divided b 1/5 in the pots, see below). Pot trials using the simulated Legacy-P soil (20% mixed with 80% non-incubated soil = without Legacy-P) and mustard (Brassica campestris) showed that plant growth responded much more to fertiliser addition (c. 0 – 200 mgP/kg soil), that is the maximum fertiliser dose was needed to achieve maximum plant growth in the soils without Legacy-P, whereas the lowest fertiliser does (50 mgP/pot) was sufficient in the pot with the highest Legacy-P. The authors conclude that Legacy-P is shown to be beneficial in improving crop response to fertiliser, effectively be preventing/reducing fixing of fertiliser P onto soil buffering sites. They underline that their results show that soil tests such as Olsen-P tend to underestimate the effectiveness of P-fertiliser application, because they involve increasing soil pH, and that P-fertilisation can be better planned if the soil P test is combined with measurement of soil buffering capacity (e.g. method Burkitt et al. 2022 or other).

“Evaluating the benefits of legacy phosphate”, N. Barrow et al., Plant Soil (2022) 480:561–570, DOI.

Stay informed

SCOPE Newsletter: www.phosphorusplatform.eu/SCOPEnewsletter

eNews newsletter: www.phosphorusplatform.eu/eNewshome

If you do not already receive ESPP’s SCOPE Newsletter and eNews (same emailing list), subscribe at www.phosphorusplatform.eu/subscribe

LinkedIn: https://www.linkedin.com/company/phosphorusplatform

Slideshare presentations: https://www.slideshare.net/phosphorusplatform

Twitter: @phosphorusESPP

YouTube https://www.youtube.com/user/phosphorusplatform

ESPP members